| LOG307: Optimisation and Simulation for Decision-Making |

You are reminded that electronic transmission is not immediate. The network traffic may be particularly heavy on the date of the submission deadline and connections to the system cannot be guaranteed. Hence, you are advised to submit your work early. Canvas will allow you to submit your work late but your work will be subjected to the mark-deduction scheme. You should therefore not jeopardize your course result by submitting your ECA at the last minute

Question 1

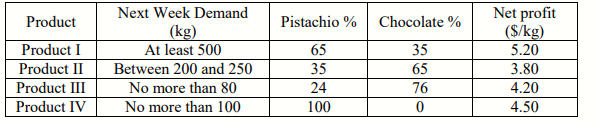

The Findik Saray, a Turkish Nut Company, makes four different products from pistachio and chocolate: Product I, Product II, Product II, and Product IV. Demand requirements for the coming week, the percentages of pistachio and chocolate, and the net profit for each product are as follows:

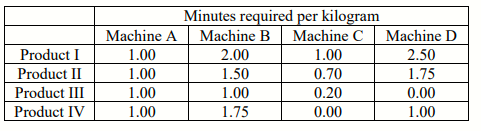

The company has 600 kilograms of pistachio and 400 kilograms of chocolate for use next week. These products are made using four different machines that each has 35 hours available in the coming week. The table below summarises the time required for each product on each machine. Each machine has:

Hakan, the operations manager, has been tasked to find a production plan that maximizes the total profit.

(a) Formulate a linear programming model for this problem.

(b) Create a spreadsheet model for this problem. Solve the problem using the Excel Solver. What is the optimal solution?

(c) If Hakan wanted to increase the production of any product, which one would you recommend? Why?

Question 2

Inventory holding cost is one of the highest costs a company incurs. Therefore, companies always try to reduce inventory costs by implementing appropriate strategies. One such company is Pepsico Foodservice. Pepsico is trying to control inventory costs for one of its products: Lay’s chips. The weekly cost of holding one carton of chips is $25. Based on the past data, it was estimated that the weekly demand of Lay’s chips averaged 120 units, with a standard deviation of 25 units. If the demand for the chips is more than the items on hand, customers would choose to buy a different brand of chips.

The production facility at Batam can change its production to 3 quantities only – 100, 120, and 150 cartons per week. But changing the production quantity is expensive; it costs $3,000 to change the production quantity.

The company is trying to evaluate the impact of the following production policies:

- Produce a quantity of 150 units next week if the on-hand inventory this week is less than 20 units (OHL)

- Produce a quantity of 100 units next week if the on-hand inventory this week is more than 80 units (OHH)

- Continue with the present production quantity otherwise. There are 75 cartons of chips in the store currently, and the production quantity is 120.

(a) Based on the above policy, construct a simulation model for one year for the production of chips. Determine the total cost. Show the change in inventory and production quantity over the weeks.

(b) Run the model developed in part (a) for 500 iterations to estimate the average yearly cost for different values of OHH, ranging from 30 to 80, in multiples of 10. Analyze what value of OHH provides the minimum cost on average. Calculate other summary statistics to have a better idea of the best value.

(c) Suggest any other production policies that might be useful to investigate.