Problem Scenario.

You are a research and development engineer for a fermenter supply company. This company specializes in the development of automatically controlled fermenters for various food products. Your company makes the marketing claim that “fermentations using our equipment rarely fail due to contamination”. Your manager, the Director of Engineering, Mrs. Diana Lang has asked you to investigate the fermentation medium sterilization procedures, as these are critical to the successful accomplishment of the claimed performance.

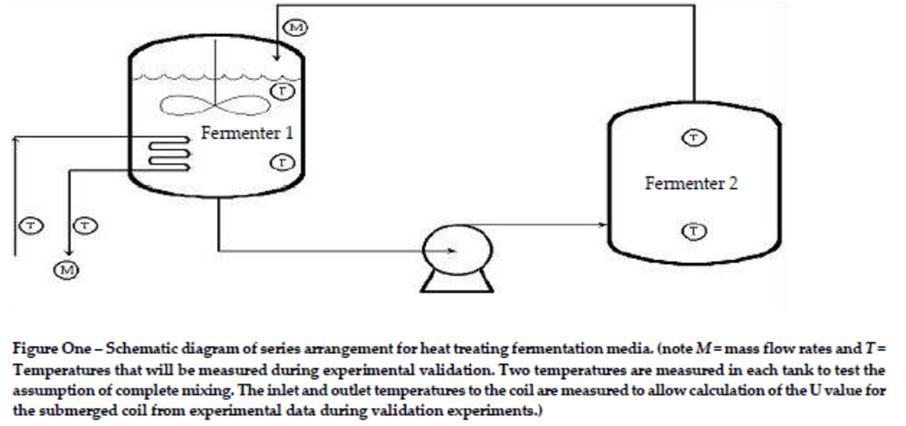

The standard fermenter design (Fermenter 1) consists of a stirred vessel with a heating coil inserted in the vessel. In situ sterilization is accomplished by filling the vessel(s) with fermentation medium, applying heat in the form of a hot fluid flowing through the heating coil, and heating for a period of time. Once satisfactory heat treatment is obtained, the hot fluid in the heating coil is replaced by cold water to cool the vessel and medium to the desired fermentation temperature.

A client has requested the addition of a second low-cost fermenter (Fermenter 2). Fermenter 2 is not Mined and does not contain a heating coil. In order to heat treat the fermentation medium in Fermenter 2, it is connected in recycle with Fermenter 1 as shown in the diagram. Thus, the medium in both fermenters can be treated at the same time, and, once cooled, the fermenters can be de-coupled and run as two separate batch fermenters.

Hire a Professional Essay & Assignment Writer for completing your Academic Assessments

Native Singapore Writers Team

- 100% Plagiarism-Free Essay

- Highest Satisfaction Rate

- Free Revision

- On-Time Delivery

It is necessary to be able to predict the length of the heat treatment necessary for the combined system so that the sterilization process can be optimized. Mrs. Lang is particularly concerned about one very expensive medium that can only be pasteurized using hot water at up to 70’C as the heating medium. This medium is heat sensitive and so even a few minutes of unnecessary treatment at high temperature will damage it significantly. In this medium, spores cannot be killed, but vegetative cells can be. It has been decided to include the destruction of Listens: monocytogenes (Dm = 16.5 s, z = 10°C) in the model.

A mathematical model is required to predict the temperature and viable Listerth concentration changing in each fermenter as a function of time for the heating stage of the process.

Stuck with a lot of homework assignments and feeling stressed ?

Take professional academic assistance & Get 100% Plagiarism free papers

Chat Now

Part A: Formulation

You are required to formulate models to describe the following processing system. You should submit a clearly presented model development using the modelling process described in the guidelines and demonstrated in lectures.

Your document should include:

- definition of the purpose of the model

- description of the system

- diagram of the systems including the processing variables

- assumptions made in the model development along with a brief justification of each

- definitions of all nomenclature used, including units and types of variables

- summary of how many equations and of what type is needed to complete the model

- formulation of equations; stating the basis of the equation, word balances, the units required for each term, and the derivation of the final equation

- initial conditions

- summary of model equations requiring a solution

You are not required to solve the model developed in Part A.

The post You are a Research and Development Engineer for a Fermenter Supply Company: Chemical Engineering Assignment, NUS appeared first on Assignment Help Singapore No 1 : Essay & Dissertation Writers, SG.